Power to the People

Having a balanced three-phase power system for your business can benefit you in a lot of ways. Having clean power and running more efficiently is a great way to save your business money on electrical bills. Single phase electricity is power from the grid that provides a single sine wave, oscillating at sixty times per second. The Alternating Current (AC) power is delivered in waves that average 120 volts, arriving sixty times per second.

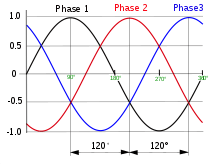

3 phase electrical power is basically 3 single phase sine waves that are offset from each other by 120 degrees, so that at any given moment, there is a wave near maximum power delivery. 120 volts arrive one hundred eighty times per second. This provides a much smoother, more consistent flow of current than single phase.

Electricity flows through high voltage transmission lines as 3 phase electrical power and then is "stepped down" to single phase power for residential consumption through the use of transformers. This is an expensive process that the consumer ultimately pays for. Some industrial facilities are provided with 3 phase service, but initial installation is costly and retroactive fitting is exorbitant.

3 phase balanced load example...

Balanced 3-phase power has 3 distinct wave cycles that overlap as shown in the above example. Each phase reaches its peak 120 degrees apart from the others so the level of power supplied remains consistent through time.

Electricity provides clean power for businesses and industry. Finding more affordable electricity makes economical sense. A single phase to 3 phase converter is the solution. A lot of equipment is available with 3 phase motors installed. Properly applied, single phase service can be converted to a balanced three-phase power system, allowing you to retain the simplicity of motors and controls. Converting your power from single phase to balanced three-phase power system is cheaper than rewiring your shop or buying new equipment.

Benefits of Balanced Three-Phase Power

- Single phase motors may not work with all machinery

- Single phase motors are typically more expensive due to their complexity

- Single phase motors may not provide adequate performance as required

- 3 phase systems utilize conductors more efficiently than single phase, consequently less copper or aluminum is needed to make them, reducing the cost of materials.

- 3 phase motors and equipment benefit from more consistent power flow.

- 3 phase motors operate more efficiently, with less vibration and noise, reducing maintenance and repair costs.

- 3 phase tools and machinery last longer, reducing the cost of replacement.

Power, Power, Power.

There are Single Phase to 3 Phase Converter choices available.

Static converters work well for small machinery loads. They utilize a relay and capacitor to facilitate starting the motor. They can be used for small drill presses or air compressors.

ADD A PHASE ® static converters produce symmetrical 3 phase current from single phase by using the motor's impedance with an autotransformer and one or more capacitors to step up the power. ADD A PHASE ® static converters can handle 1-100 horsepower loads and have been proven on numerous pieces of equipment, including pumps, fans, and compressors. Motor speeds between 3,600 RPM and 1,800 RPM can be accommodated. ADD A PHASE ® 3 phase power converters limit inrush current upon starting, provide appropriate current to multiple motor operation, allowing machines to operate efficiently at maximum capacity.

Rotary phase converters, most simply put, are static converters with idle running motors. This allows you to run larger or multiple motors. The base unit functions with a capacitor panel to convert single phase to 3 phase power. Additional capacitor panels can be added to accommodate larger motors or multiple machines.

Dyna-Phase rotary phase converters allow 3 phase operation of a single load from a single phase disconnect. Model 1 is ideal for centrifugal pumps, fans or conveyors with automatic controls.

Our Dyna-phase Units is designed for heavy duty loads, including large air compressors, sealed refrigeration units, and submersible pumps. The voltage regulated units (V Reg) can run multiple heavy duty motors up to the rated capacity.

Dyna-Phase units can be customized to the clients needs. Custom options include:

- 230 V, 460 V, and 575 V output

- Automatic voltage control for multiple motors

- Special enclosures available (NEMA 1 enclosure is standard)

- Ballasts to increase capacity

- Operation can be manual or automatic

Some industries that can benefit from the implementation of 3 phase power converters include:

Balanced three-phase Power for Businesses

- Woodworking Machines

- Metalworking Machines

- Welding

- CNC milling

- Commercial construction

- Excavating

- Irrigation

- Hoisting and lifting stations

- Grain dryers

- Greenhouses

With today's push for clean power for businesses, the need for environmental responsibility, and greater economy, converting single phase power that is already available, to 3 phase power that is more efficient, is a "no brainer".

Whatever your industry needs to power up, Precision Motor Repair is approved by the Canadian Standards Association and is ready to serve you. Their licensed electricians and trained staff can provide equipment, service, and repair of your motors, as well as providing 3 phase power options for your business throughout eastern Canada. Their 24/7 customer service line, manned by licensed electricians, is always available to walk you through or trouble shoot any problems.

Located in Leamington Ontario, Precision Motor Repair is looking forward to servicing customers throughout:

- Halifax

- St. Johns

- New Brunswick

- Nova Scotia

- Charlotte Town

- East Coastal Canada

For more information, you can visit our contact page at http://precisionmotorrepair.com/contact/ or feel free to call (519)322-1363 to learn how Precision Motor Repair can improve the functionality and economy of your business or industry by installing a balanced Three-Phase Power system.